The Role of Assist Gases in Metal Laser Cutting

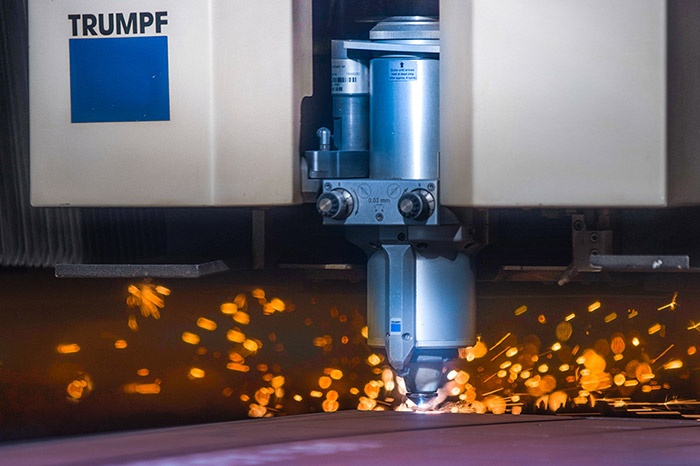

Laser cutting has become one of the most effective ways to slice through metal with accuracy and speed. This process uses a high-powered laser beam that melts or vaporizes the metal. In metal laser cutting, assist gases play a major part in making the cut cleaner and more precise.

How Assist Gases Help the Cutting Process:

Assist gases blow away molten material from the cut zone. This keeps the laser focused on cutting through the metal without interference. Without this gas, the melted metal would pool around the cut, leaving a rough and uneven edge. The gas also helps maintain the right temperature by cooling certain areas during the process.

The Types of Gases Used:

Different types of gases are used depending on the metal being cut. Oxygen is often used for thick steel because it reacts with the hot metal, increasing the heat and speeding up the cut. Nitrogen is common when cutting stainless steel or aluminum, where clean, non-oxidized edges are needed. Compressed air is a cheaper option for thinner metals and is sometimes chosen when cost matters more than finish.

Gas Pressure and Nozzle Design Matter:

The way the gas is applied also affects the quality of the cut. High-pressure gas can remove molten material faster and create narrower cuts. Low pressure may work better for soft metals or delicate work. The nozzle, which directs the gas flow, has to be the right shape and distance from the surface to keep the cut steady and focused.

Safety and Speed Benefits:

Using the right assist gas makes the entire process safer and faster. The gas clears away sparks and hot material that could cause damage or injury. It also lets the laser move more quickly across the metal because there’s less resistance. This helps workers complete more tasks in less time without losing quality.

Waste Reduction and Cleaner Results:

When the right assist gas is used, there is less need for post-cut cleaning. Smooth edges reduce the time needed for grinding or polishing. This helps save time in the workshop and keeps the final product looking better. It also helps limit the amount of scrap metal created during cutting.

Assist gases might seem like a small part of the laser cutting setup, but they play a big role in shaping how well the job turns out. Choosing the right one and using it properly can make all the difference in how smooth, fast, and clean the cut is.